Siemens, a giant in the automation industry, once again cast a gravel in the long history of simatic products, causing a ripple. The name of this gravel is called s7-1200, which is more like a s7-200 in terms of product naming. Extension or upgrade, here I want to explain this product in detail. Before explaining it, I think I should learn about the family history of Siemens plc.

1. The history of Siemens plc

Since Siemens entered China in 1872, the road of China’s automation has been accompanied by Siemens automation products. When it comes to Siemens plc, everyone can name the familiar models s7-200/300/400, but You may not know that not all of these products are of Siemens German origin. S7-300/400 uses step7 programming while s7-200 uses step7micro/win programming. Many people once sighed why they are familiar with s7-300. Learning s7-200 products after the product seems to be a company product and need to learn from scratch and vice versa. Why is this? This is because the s7-200 product was developed by Siemens using an acquired American company to develop software and products, and was integrated and listed in order to be able to compete for the low-end plc market. I believe everyone can also see that the programming mode of s7-200 and sm special register settings can find some traces of American and Japanese plc programming mode, and Siemens has been looking for the right time to develop low-end plc products of German descent, in 2009 In s7-1200 this product came into being.

2. The market positioning of s7-1200

Some control friends said that s7-1200 is a simple upgrade of s7-200. You can say that you know it, but you don’t know why, because it is indeed not an upgrade but a replacement. Why do you say that! Because this product of s7-1200 is a punch of Siemens’ low-end plc products. Siemens has stopped the s7-200 production line except for the s7-200cn series in China. With its low price, s7-200cn is also competing for the automation market share of the third developing country. The low-end markets in Europe and the United States will all be covered by s7-1200 products. Many manufacturers in China have successively launched modules compatible with s7-200, which also allows Siemens to occupy a part of the low-end market. Therefore, in order to reduce costs and maintain the market, it is necessary to continue the glory of the 200cn series, and Siemens will use the latest communications Similar to the application of control technology in the s7-1200 product, Siemens will also use the s7-1200 product to build a global plc mid-to-low-end market.

3. The product positioning of s7-1200

The positioning of the s7-1200 product is quite clear. It is aimed at the low-end small plc product line. The hardware structure is composed of a compact modular structure. The system IO points and memory capacity are both It is 30% more than s7-200, which fully meets the market demand for small plc. Now many small units and system points in discrete industries and process control industries are within 200 discrete points and 36-48 points for analog points. Therefore, at this time, the s7-200 will not be able to deal with it. Customers can only purchase the s7-300 medium-sized plc to face the project in the form of a large horse-drawn trolley, which also caused a certain cost to the customer. The capacity design of the s7-1200 product is based on fully accumulating customer needs for many years.

4. New features of s7-1200 products

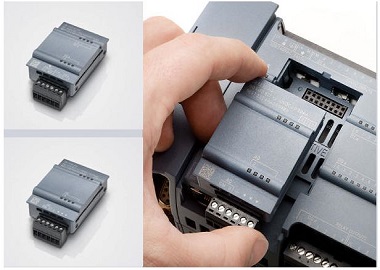

a) Compact modular structure

The s7-1200 product continues the 200 compact structure, the width of cpu1214c is only 110mm, and the width of cpu1212c and cpu1211c is also only 90mm. The volume of the communication module and the signal module is also very small, making this compact modular system greatly save space, thus providing you with the highest efficiency and flexibility during the installation process. In addition, s7-1200 adds a special structure of the io module called the signal board, which is embedded in the cpu box, respectively 2di/o and 1ao. This is the essence of Siemens design. The io module that needs to be supplemented can be customized at any time. The highlight of the problem of small projects is the uncertainty of the project. It is very likely that di/o and ao are not enough in the process of project implementation, while ai can be a richer signal channel.

b) Powerful control function The

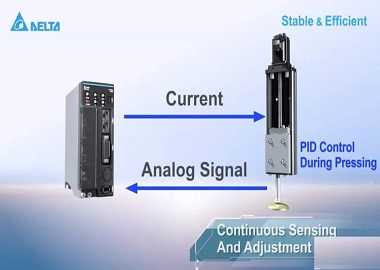

system integrates 16 pid control loops, and pids are all fast function blocks that can support self-adaptation, and provide a control screen for pid parameter debugging and observation, which allows users to be unfamiliar with pid parameters How to adjust the process parameters to the required standards. The system integrates up to 6 high-speed counters (3 100khz, 3 30khz) for precise monitoring of incremental encoders, frequency counting or high-speed counting of process events. The system integrates 2 high-speed outputs, which can be used as high-speed pulse output or pulse width modulation output. When configured as pto, they will provide a high-speed pulse output with a maximum frequency of 100khz and a 50% duty cycle for open loop speed control and positioning control of stepper motors or servo drives. The high-speed pulse output is internally fed back through two high-speed counters. When configured as a pwm output, it will generate a fixed period output with a variable duty cycle to control the motor speed, valve position or the duty cycle of the heating element. The system supports open loop speed control and position control of stepper motors and servo drives. The configuration of this function is very simple: It can be realized by an axis technology object and a general plcopen operation function block. In addition to the home and jog functions, it also supports absolute, relative and velocity motion.

c) Classic programming mode

s7-1200 uses the simaticstep7basic tool for programming, and the use of this tool is basically the same as step7professional. It provides two programming languages, lad and fbd, and uses ob organization block fb function block fc function function db data block programming form (through the background db Support can realize the parameterized call of function blocks), this time Siemens finally unified the programming style of the whole line of products.

d) Complex

data structure What does complex data structure mean! In fact, it is a data unit composed of multiple elements such as arrays and structures. There are few low-end PLC programming languages on the market that can support complex data structures. They all use flat data types (bool, int, word, dword, real). The s7-1200 product inherited the data structure possessed by the 300/400 mid-to-high-end plc and began to support arrays and structures.

e) The polymorphism of instruction parameters is

consistent with data type classification in Siemens’ classic programming instructions. For example, the instructions of addition/subtraction/multiplication/division are different instructions according to different data types. When programming, regardless of the data type, it just calls the function. When the function block is placed in the network, the user will be allowed to choose which data type it is, which easily realizes the polymorphism of the parameters.

f) Programming based on control objects

As mentioned above, s7-1200 adds db data block and struckt data type. It is precisely because of these two necessary conditions that a very important function of this system is introduced. This is based on Editing and programming of control objects, adding control objects only requires one click. When adding a new object (such as an axis or a pid controller), the relevant settings will be displayed in the “add new object” window of the engineering system. Name the object according to its function. When fine-tuning various objects, the user can use the function description. After all the information of the object is assigned, the object will be opened in the editor immediately.

g) Integrated hmi engineering configuration

simatic step 7 basic includes powerful hmi software simatic wincc basic, which is used for efficient programming and configuration of simatic hmi streamlined series panels. Efficient engineering configuration includes, for example, direct use of controller process values in hmi projects through smart drag-and-drop functions. hmi is part of the entire project, hmi data can always be consistent. The connection between hmi and plc can be centrally defined. You can also create multiple templates and assign them to other screens. The fully integrated hmi function makes it very convenient and efficient to configure the simatic hmi streamlined series panel.

h) Communication integration profinet interface.

In the current trend of automation and esteem industrial Ethernet communication, Siemens’ full line of products have begun to “top helmet” and all are equipped with profinet interfaces, but the low-end product s7200 still stays on Ethernet. On this level of the communication s7 protocol, why is this! Because Siemens has already led the market with the s7-1200 with profinet interface. s7-1200 supports traditional Ethernet s7 communication and also supports Profinet industrial Ethernet bus communication. It is mainly used for simatic hmi streamlined series panels (for visualization); other controllers (for communication between PLCs); third-party equipment ( For optional advanced integration)

i) Flexible third-party communication

Communication with third-party equipment has always been the weakness of plc automation manufacturers, and s7-1200 is equipped with a cm module to support rs232/485 and its own Ethernet port communication. For serial communication rs232/485, the use of function block configuration frame communication is used to complete data flow communication, and s7-1200 supports the encapsulation of send_ptp and rcv_ptp function block serial communication. This means that it is easy to encapsulate various serials. Protocol. For the Ethernet s7-1200, it provides two communication methods of tcp and udp, and provides a standard t-send/t-receive function block to complete the communication solution. For example, these two sets of instructions can be used to encapsulate modbus-tcp The protocol library is provided to users. In addition, the system provides a rich character processing command library (left, right, delete, insert, replace, val_strg, strg_val and s_conv), which means that this product has enhanced the ability of this product to process ascii characters in communications, and can communicate with a large number of third parties. Carry out custom character communication (weighing, secondary instrument, single-chip computer, etc.).

5. The product outlook of s7-1200

The above mentioned so many features of s7-1200, but it does not mean that this product has no shortcomings, “there is no perfect person” and this product is still in the process of growth. , It is not perfect in many functions, such as: does not support profinet cab and io configuration; does not support ppi, mpi and profibus communication; does not support formula functions, etc., but these functions are not a problem for Siemens development. This is only for Siemens In the morning market, some communication modules and software functions will be launched and planned in the next version of the software, so users can now use this product according to local conditions and according to their project scope. With the rapid recovery of the Chinese economy and the economic development of Europe and America Recession, now is the situation of a large number of Chinese equipment exports, and the s7200cn series cannot be exported to Europe and the United States without ce certification, and s7-1200 is a good low-end compact plc product, which is very suitable for small and medium-sized development projects and equipment , And if you need to communicate with a large number of third-party devices, this product really makes the best use of it. I feel here that this product will blossom everywhere in the automation market in the next three years.