1. American manufacturer Rockwell AB Rockwell’s PLC mainly includes: PLC2, PLC3, PLC5, SLC500, ControlLogix and other models. PLC2 and PLC3 are early models. The most used small PLC is SLC500, and the medium-sized PLC is generally ControlLogix. Use PLC5 series. The DF1 protocol is a communication protocol supported by Rockwell PLCs. The DF1 protocol can transmit data through serial media such as 232 or 422, and can also be transmitted through network media such as DH, DH+, DH485, and ControlNet. The specific content of the DF1 protocol can be downloaded from AB’s database. AB’s PLC also provides OPC and DDE, and its integrated software includes DDE and OPC SERVER in RSLogix, and data communication can be carried out through the above software. AB’s medium and high-end PLCs also provide high-level language programming functions, and users can also implement their own communication protocols through programming.

2. GE currently uses 90-70 and 90-30 series PLCs in China. Both PLCs support the SNP protocol. The SNP protocol contains the specific content of the protocol in its PLC manual. Now GE’s PLC can also be connected via Ethernet. GE’s Ethernet protocol content is not publicly disclosed, but GE provides an SDK development kit, which can be used to communicate based on this development kit.

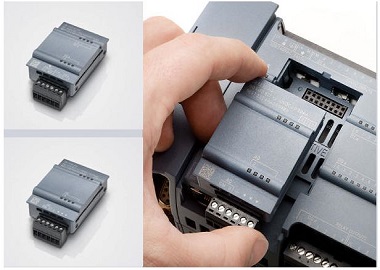

3. The Siemens series PLC mainly includes its early S5 and the current S7-200, S7-300, S7-400 and other types of PLC. The early S5 PLC supports the 3964R protocol, but because it is less used in China now, it is not polarized. Outside of individual renovation projects, there are few data communications with them. S7-200 is a small-scale Siemens PLC. Because of its low price, it has been widely used in China and supports MPI, PPI and free communication port protocols. Siemens 300 PLC supports MPI, and it can communicate with computers via Profibus and industrial Ethernet bus systems. If you want to complete point-to-point communication, you can use CP340/341. As a large-scale PLC of Siemens, S7400 provides quite complete communication functions. It can communicate through S7 standard MPI, and at the same time it can communicate through C-bus, Profibus and Industrial Ethernet. If you want to use point-to-point communication, S7-400 needs to pass the CP441 communication module. The communication protocol of Siemens is not disclosed. Many configuration software supports communication methods such as MPI and PPI. Profibus and Industrial Ethernet generally communicate data through Siemens software.

4. Schneider (Modicon) Schneider has more PLC models and more domestic applications. Its communication method mainly supports two communication protocols, Modbus and MODBUS PLUS. The Modbus protocol has been widely used in the industrial control industry. It is not only a PLC communication protocol, but also has a wide range of applications in smart meters, inverters and many other smart devices. MODBUS has undergone further development, and now has MODBUS TCP mode, which is used for transmission via Ethernet, and the communication speed is faster. Compared with MODBUS, Modbus PLUS has a faster transmission speed and a longer distance. This communication method requires the installation of the SA85 card provided by MODCON on the computer and the driver of the card to communicate. In addition to the above two methods, Modicon’s PLC also supports multiple communication methods such as TCP/IP Ethernet, Unitelway, FIPWAY, FIPIO, AS-I, Interbus-s, etc.

5. Omron series PLCs are also popularized in China. In terms of communication methods, OMRON currently mainly uses two communication methods: Host Link protocol is a communication method based on serial port for data transmission. When PLC enters MONITOR mode, the upper computer can communicate with Omron PLC. When communicating with Omron, pay attention to leave a certain amount of time between two communications. If the communication speed is too fast, it will easily cause PLC communication abnormalities. ControlLink is a fast communication method of Omron PLC. Control Link carries on the data communication through the board card, there is a data exchange area between the board cards, the board card realizes the data exchange to complete the data collection function. To use this method of communication, Omron’s driver must be configured.

Sixth, Mitsubishi PLC’s small PLC is widely used in China. Mitsubishi also has many PLC models, mainly including FX series, A series and Q series. There are many communication protocols for Mitsubishi PLC series, and each series has its own communication protocol. For example, the FX series includes communication via programming port or 232BD, and communication via 485BD. Its A series and Q series can communicate via Ethernet. Of course, Mitsubishi PLC can also communicate via CC-LINK protocol.

7. Panasonic PLC and computer can communicate through serial port and Ethernet. The communication protocol adopted is MEWTOCOL protocol. Like most Japanese PLCs, the MEWTOCOL protocol is relatively simple. Many softwares can read data directly from the PLC.